The organic amine solvents include N-Methyldiethanolamine CH3-N=(CH2CH2OH)2 (MDEA), Diethanolamine (DEA) and Ethylenediamine (EDA), etc. , which are widely used to adsorbed and remove SO2, H2S and CO2 gas from the exhausted gas in petroleum refinery industry.

Due to the repeatedly used of amine solvent, it results in the decomposition and oxidation of MDEA, and contamination by powders of coke. These cause foaming of MDEA, that results in blowing off a large amount of amine solvent, increasing its viscosity, blocking the treatment unit, polluting the exhaust air. Sometimes it can shutdown the process for emergency maintenance. In order to reduce the impact of contaminates and degraded component of amine, it often requires a purification of solvent by folded filter, mechanical filter with a large pores filtration.

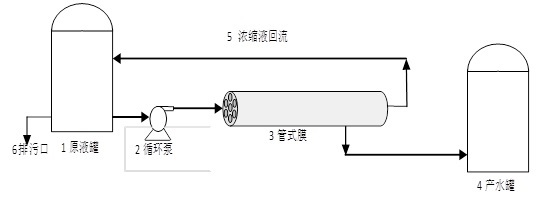

Highnew provides a highly efficient “membrane”, which is simple in structure, easy to operate, filtration with small pores. The process flow diagram shows as following.

Highnew uses a tubular membrane system to purify the amine. The system includes

1 Raw amine tank is connected with

2 Recirculation pump with a pressure in a range of 0.1 to 0.4 MPa. The raw amine reagent gets through

3 tubular membranes in a cross-flow patterns, whose openings are in size between 0.05 and 0.1 um. The filtered amine solvent then flows into a

4 storage tank. The concentrated rejection stream returned to raw amine tank by a

5 piping system. The settled particles from the raw amine are discharged through an

6 outlet. The tubular membrane uses a new material that is anti- acid, alkali and amine solvent with its opening in a range of 0.05 to 0.1 um.

Case study:

A petroleum refinery selected 30%-40% MDEA solvent as a sulfur absorbent. During the operation, there is significant degradation when the solvent recycled. There were a lot of contaminates from the reaction of amine that forms a series of degraded particles. The performance of the tubular membrane of Highnew is shown as the following.

MDEA | Suspended Solid | Color |

Before | 114mg/L | Deep red |

After | <10mg/L | Light yellow |

The left side one is before the filtration and the right side one is after the filtration.