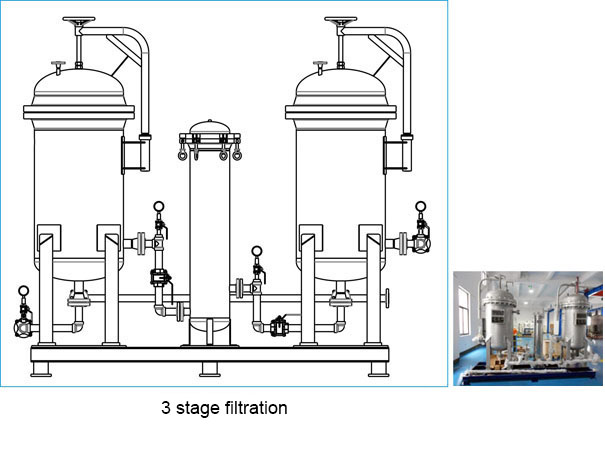

HighNew three-stage filtration system:DE-SS+DE-HC+DE-SS Based on extensive engineering experience, HighNew has developed and imported a new generation pretreatment system in series that consists of Suspended Solids Filter (DE-SS) + Hydrocarbons filter (DE-HC) + Suspended Solids filter (DE-SS).First Stage: High Flow Pleated cartridge Filter(Filtration Precision <10μm)Second Stage: High Effective Activated Carbon Filter Third Stage: High Flow Pleated cartridge Filter (Filtration Precision <1μm)The filtration system has three stages to remove suspended solids and hydrocarbons. The max flow rate is up to 30T/hr. All three filters are skid-mounted, so the system is compact, easy to operate and move with high efficiency. This system has been widely applied on the market.

Advantages:

Source and impact of the Amine contaminates

Source and impact of the Amine contaminates

Source of Amine contaminates

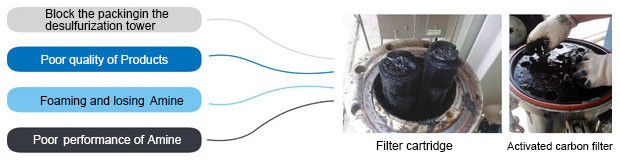

In amine desulfurization process, contaminates come from the dissolved the equipment corrosion; adsorbed the Suspended Solids (SS) and Hydrocarbons (HC) from the raw material, which forms something like shoe-polishing material. The main contents of contaminates are FeS, shoe-polishing material and coke powder etc, which are the main substances that make Amine look like a black and sticky soup.

Dangers of Amine contamination

Theexistence of the above contaminateswill have a significant impact onthe Amine performance and treatment process as the following:

The necessity and difficulty of Amine treatment,

Amine treatment is aprerequisite for the stable performance of the desulfurization system. The suspended solids and hydrocarbons in Amine have tobe removed first to ensure the successful of resin exchanging on HHS . The key factors impacting the efficiency of the treatment are the type of filtration, filter media and flux that strongly impacts on the operational stability and the maintenance cost of the Amine treatment system.

Commonly used filtration flow diagram and equipment

We usually use a side-stream filtration in three stages to pre-treat Amine. It is difficult to remove suspended solids by a two-stage filtration system because the contaminator’s particle size ranged from 0.1 to 200 μm. HighNew has extensive experiences in Amine treatment, and able to provide a professional expert consultancy.

Typical contaminated Amine filtration system consists of two cartridge and one activated carbon filters which are arranged in series. The activated carbon filter is normally located in middle.

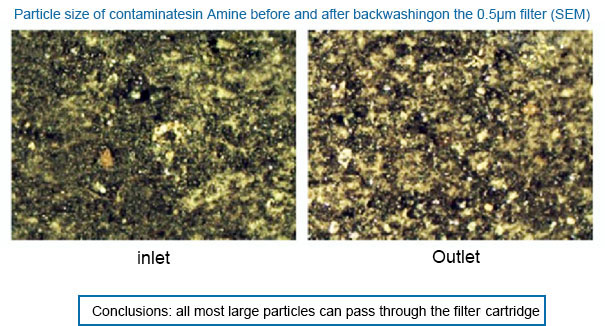

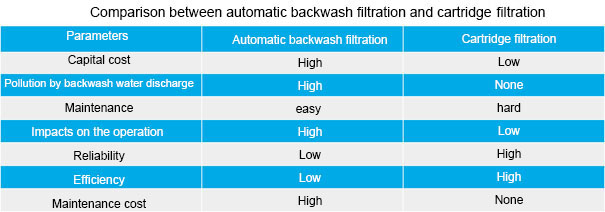

Comparison between automatically backwash filter and cartridge filter

Automatic backwash filter is not suitable for Amine treatment, It becomes a rule of thumb in China since 1999.

The backwash filtration can be easily blocked, no matter which kinds of media is used. Since the contaminates has a wide range on the particle size with highly viscosity, which can easily adsorbed onto the filter media, but hardly to be backwashed out. It causes too many troubles as follows:

Comparison between automatic backwash filtration and cartridge filtration

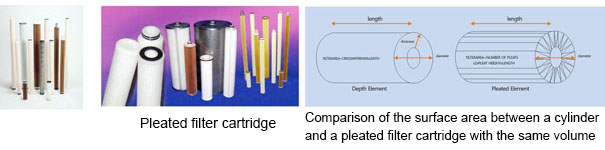

The particle size of contaminates in Amine is generally ranged from 0.5 to 200 microns. These particles are hard to be removed by backwashing, and sometimes it blocks the filter media, results in a frequently backwashing. However the backwashed filter is still unable to work properly. These particles could be removed by a series of cartridge filters with gradated sieve, multiple levels, three-dimensional and curved channels.

Cartridge Filter don’t backwash, which can reduce rinsing water and power consumption for the backwash. Furthermore, there is no discharge of the backwash water as well as the impacts on the performance of wastewater treatment plants onsite, particularly the surge load of the residual organic Amine in the backwash water will makes a lot of trouble for discharging.

The advantages of HN High Flow Pleated Cartridge Filter (DE-SS)

We introduced the high flow pleated cartridge filter from the United States, which has the large effective surface area, high performance, high flow capacity and the high pollutant-carrying capacity.

Introduction on HN-Activated carbon filter system (DE-HC)

HN-Activated carbon filter system (DE-HC) uses the typical activated carbon, which has large specific surface area, strong adsorption ability, high capture capacity, strong decolonization and great pass through capacity. The contaminates (hydrocarbons) in Amine are removed by the mechanisms of flocculation, adsorption and interception. Perforated pipe and a layer of small inert micro porous ball are used to achieve an even ly distribution of water. Furthermore, it protects the activated carbon media from the flush out of the system. The main equipment has been compactly built and takes a small footprint. It also has been built with manholes and hand holds for the maintenance convenient.